can you put wood in a kiln

You should not put a kiln directly on a wooden floor. Step 1-Prepare the Oven.

Drying 650 Bf Of Walnut In A Homemade Kiln R Woodworking

Then youre not carrying the correct thing or youre not using the kiln and are trying to put wood in the smelter.

. The conventional or solar kiln drying process can be used to dry timber to any desired low moisture content but in air drying moisture contents below 18 are difficult to achieve. If you are going to locate the kiln somewhere that there will be non-fire-proof surfaces you can make them fireproof by covering them with cement board. All surfaces within 3 feet of the kiln need to be fireproof.

Set the wood racks position properly. Our recommendation is that you make the Charcoal Kiln first. I dropped the wood and picked it back up and still the kiln said I did not have processable items.

In other words you cannot charge extra to cover any extra costs involved in fast processing. The Temperature required depending upon your Elevation might only be 90 Degrees. We air dry for about one month then rack the wood in the kiln and use a dehumidifier and small fan.

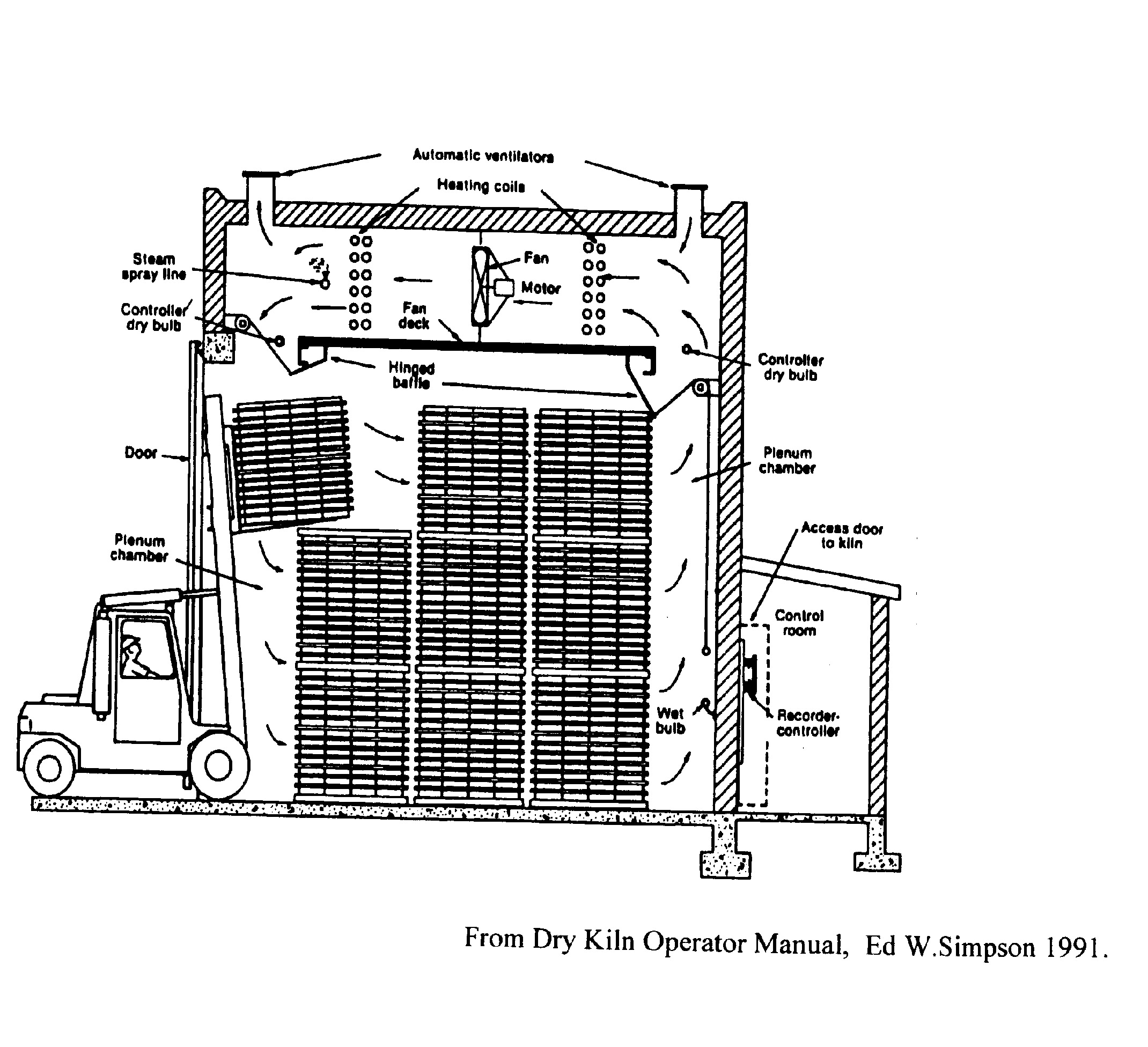

Compared to solar kiln drying conventional kiln drying takes considerably less time to dry. With a kiln you can control the environment such as temperature humidity and steam levels for a set period of time. Due to the high temperatures firing a kiln releases volatile compounds into the air many of which are toxic.

The reason we say this is because the Kiln turns Fine Wood Core Wood and regular Wood to Coal at a pretty quick clip. How Long Does It Take For Wood To Naturally Dry. With the insulation we can use the kiln in the winter in Ohio as the returned heat from the de-humidifier and the fan motor are sufficient or we can add a small heater.

Why is this important. Here is the step by step Klin dry wood making process. Turn on the convection fan if your oven has one.

Is it made of the right material a wooden shed is not a good idea as its too flammable. And have at least 2 of non-combustible boards underneath the kiln. For example kiln drying from green to 7 percent moisture content might range from 18 days for 44 lumber to 32 days for 64 lumber to 55 days for 84 lumber.

It can be constructed in any style with architectural features that match or complement an existing home. That includes the amount of moisture in wood the bunch you have to dry and how fast you need to use it. Allowing you to dry wood to the desired moisture content faster than air-drying.

A shed kiln is an attractive alternative for a couple of reasons. Cement board comes in 4 x 8 sheets usually from Home Depot type places. Yes there is no problem with that but there are different factors that play a part.

This technique will be able to dry small pieces of wood as long as you maintain the temperature. Built properly a shed kiln may even increase the value of a property. How To Kiln Dry Wood For Smoking.

It seemed to resolve itself after I restarted the game though. The oven will reduce moisture content in a matter of hours allowing you. Can Wood Be Dehydrated.

Because the supply of kiln dried hardwoods is so large in the USA it is difficult to benefit from being able to go from tree to finished lumber in a week or so. Kilns can be quite safe to use even at home when you follow some basic precautions. It is used under tile floors and walls to cement the tile to.

Kiln dried wood typically sells for a third more than green lumber and eliminates the need for customers to incur costs associated with drying lumber before use. This should extend at least 12 from the base of the kiln. In a word- No.

Drying wood in a kiln is the quickest and the most efficient way to season wood. But if you dont have a kiln then you may improvise with your own kitchen oven. Kiln drying lumber is a simple cost effective method recommended for anyone who wants to increase profits by selling dried lumber.

The Wood-Mizer KD series of lumber kilns feature 100 corrosion resistant. Can you put wood in a kiln. If you are going to attempt to Kiln Dry any Wood.

This article is for informational purposes. Alternatively if you dont have an existing shed then you could consider installing one. The kiln is nearly air-tight and the de-humidifier drains through the floor.

The temperature must be 215-218 degrees Fahrenheit in. Preheat the oven to between 200 and 225 degrees F 95 to 110 degrees Celsius. You will need to use these safety procedures and.

Effect of thickness on kiln-drying time of red oak. With a well-designed dehumidification kiln hardwood lumber can be dried for mere pennies per board foot. Or you have a bug.

You might be better off using a Vacuum Pump like those that are sold to repair Refrigeration Units on vehicles. However provided that your shed meets the other criteria below then you might consider converting it into a studio space. It shoots out one Coal every fifteen or so seconds and you can store up to 25 units of wood at a time.

As long as the dehydration process does not cause damage to the items they can be sterilized in a kiln. Lumber that is miscut is likely to vary considerably in thickness across the width and along the length of the piece. This should happen after 15 minutes have passed.

Is it large enough to accommodate a kiln. However a wooden floor can be acceptable if you use the stand the kiln was supplied with. If your Wood is placed within a Chamber that has been evacuated of the air surrounding us and heated.

Put a thermometer far from the racks and place a large sheet on the rack. There are plenty of items that can be sterilized in a kiln including food preparation supplies metal instruments and wood. Kiln-dried wood is wood that has been dried in an oven kiln.

Prepare the racks to fit the pieces of wood with plenty of space for air to move.

Home Made Wood Kiln And Working From Home Wood Kiln Kiln Dried Firewood Solar Kiln

Everything You Need To Know About Kiln Dried Wood In A Nutshell

Drying Wood With Dehumidifier Wood Kiln How To Dry Wood Youtube

Diy Firewood Kiln Wood Kiln Kiln Dried Wood Solar Kiln

What Is Kiln Dried Lumber And How Is It Used When Building A Home

Logosol Sauno Wood Drying Kiln How To Build And Set Up Youtube

My Wood Drying Kiln Wood Kiln Corner Wood Stove Kiln Dried Wood

7 Ways To Build A Kiln For Pottery Easy Diy Kiln Ideas

Simple Diy Wood Drying Kiln Youtube

A Simple Approach To Drying Lumber Woodshop News

How I Built A Wood Kiln Out Of A 20 Shipping Container Steemit

How To Make A Diy Kiln Potterymastery

Fundamental Aspects Of Kiln Drying Lumber Oklahoma State University

Buying Live Edge The Top 5 Questions To Ask Before You Buy Live Edge Slabs The Wood Cycle Of Wisconsin

Leaving A Legacy What Happens To Wood Inside The Dry Kiln Wood Floor Business

Everything You Need To Know About Kiln Dried Wood In A Nutshell

Kiln Dry Wood At Home Step By Step Method Garden Tool Expert